MSC

Book and Document Leafcaster

Book and Document Leafcaster

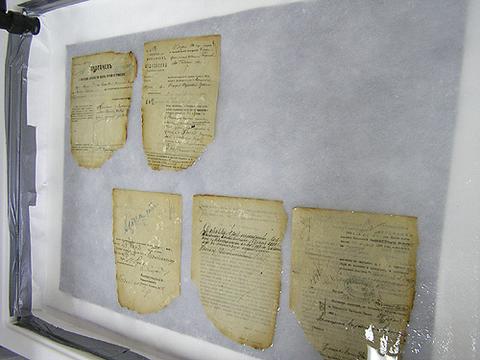

Documents with tears, holes, burns, or other losses can be stabilized and protected through a process called Leafcasting. The Leafcasting process uses paper pulp suspended in water and powerful levels of suction to create new paper that is drawn into the losses and integrated with the original paper.

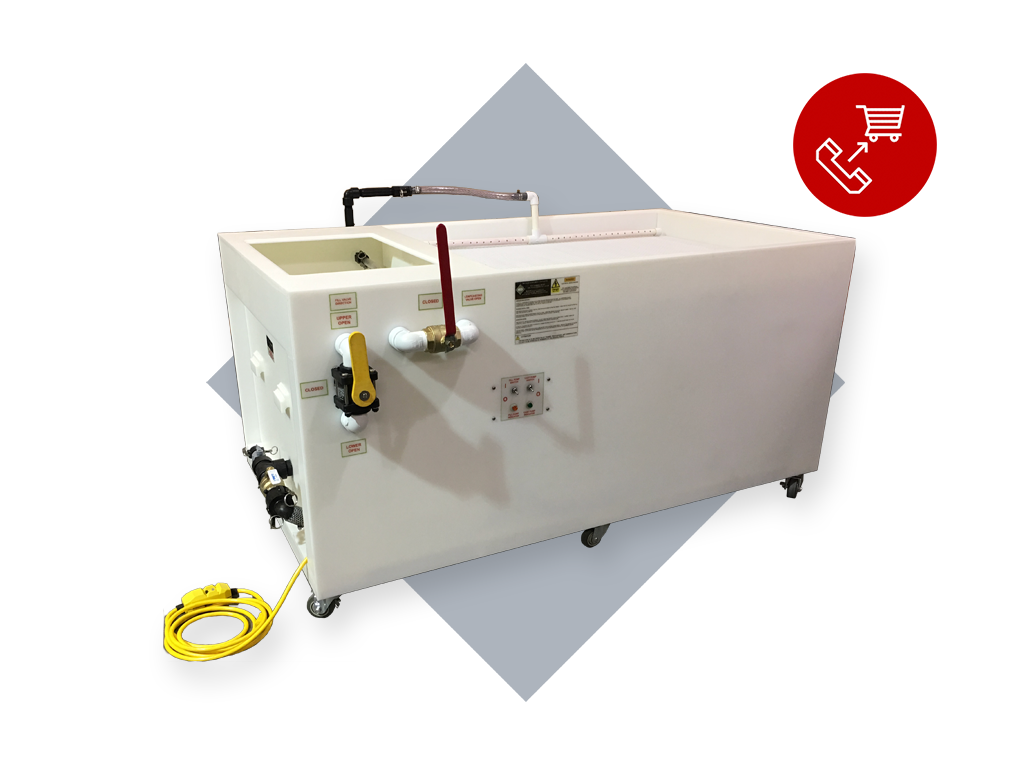

The Book & Document Leafcaster conserves and restores many items including books, printed documents, newspapers, manuscripts and works of art on paper. With a large working area and water capacity, the Leafcaster saves on time and labor over painstaking manual repairs while providing excellent, consistent results.

The Leafcasting process creates new paper at the holes and edges of a paper artifact. Paper pulp suspended in liquid slurry is pulled through a screen by a powerful suction motor. The filter screen prevents pulp from passing through it, leaving pulp deposits in the holes and edges. The excess water is pumped to the Water Holding Tank. The water is reusable for multiple castings. The new pulp binds to the original document, creating a uniform and stable sheet of paper. No adhesives are required. Alternatively, the Leafcaster can be used to cast entire sheets of paper for use in conservation. Even extremely thin gossamer sheets can be cast for use on other documents.

The Leafcaster package includes:

- Book & Document Complete Leafcasting Unit

- Two water suction pumps

- Lockable Casters

- Ground Fault Circuit Interrupter

- PVC spray fill bar

- Removable Water Holding Tank with easy drainage

APPLICATION

Leafcasting mechanically stabilizes paper weakened by holes, ragged borders, or other types of loss. Turn the machine on and turn a valve to start the water flow. Clean water fills the casting tank work area, wetting the documents to be conserved. A prepared pulp mixture is added to the water. With the flip of a switch, the suction pumps are activated, and by turning a valve, the casting tank work area is rapidly drained, removing all of the water but leaving the paper pulp behind, filling in all of the losses and empty areas on the casting tank work area. The casts are removed from the machine, flattened and dried, and the entire process can be quickly reset and repeated for the next casting.

The Book & Document Leafcaster is designed for fast and multi-sheet repair projects. Simple manual controls mean maintenance-free operation compared to Leafcasting machines with hydraulic or pneumatic valves. The design of the machine allows the conservator to concentrate on the casting process, not the mechanical operation of the machine. Casting operations can be repeated as quickly as once per minute. Operator intervention is instantaneous at any step in the casting process.

Pulp mixtures are created and calculated for each specific document. This can be done manually by counting the open squares of the lost area, or the optional PageSizer Software can calculate the loss area and compute the correct slurry mixture automatically.

FEATURES

The Book & Document Leafcaster is easy to set up, straight out of the crate. Only minimal assembly required. Constructed of white high-density polyethylene, all of the machine's surfaces are durable, waterproof and maintenance-free. Clean with only soap and water. The cabinet contains a built in casting tank and a removable water holding tank. Included with each machine is an aluminum support, a plastic casting screen, Tyvek masking dam (to reduce the casting area), Reemay polyester sheets for document handling, a plastic hold-down grid with handle, and a cover for the casting tank. Water used in the casting process is recycled, so new water is not needed for repeated castings.

The Leafcaster unit is on locking casters, for easy positioning and locking into place during use. When work is done, cleanup is easy. The casting screens and aluminum support are removable for cleaning and drying. Water can either be stored until the next session in the holding tank, or the drainage valve can be opened and all of the water removed from the machine for long-term storage. The water connection hoses are fitted with quick release connections to allow for easy removal, inspection and cleaning. Extended maintenance consists of cleaning the detachable hoses and the holding and casting tanks periodically.

All Book & Document Leafcasters are equipped with Ground Fault Circuit Interrupter (GFCI). A GFCI is an electrical wiring device that disconnects a circuit, depowering the machine whenever it detects that the electric current is not balanced between the energized conductor and the return neutral conductor. This protects against surges and electrical dangers from spilled water while the Leafcaster is in operation.

Share